About Us

A family owned and run business that has been in the toolmaking industry since 1970. Our size enables us to develop a truly personal service with our clients but with the experience to confidently undertake challenging projects.

We are able to provide small batch heat treatment in house to enable fast turnaround times. With our proven track record we have been able to develop long standing relationships with many of our customers worldwide, who often return with repeat orders.

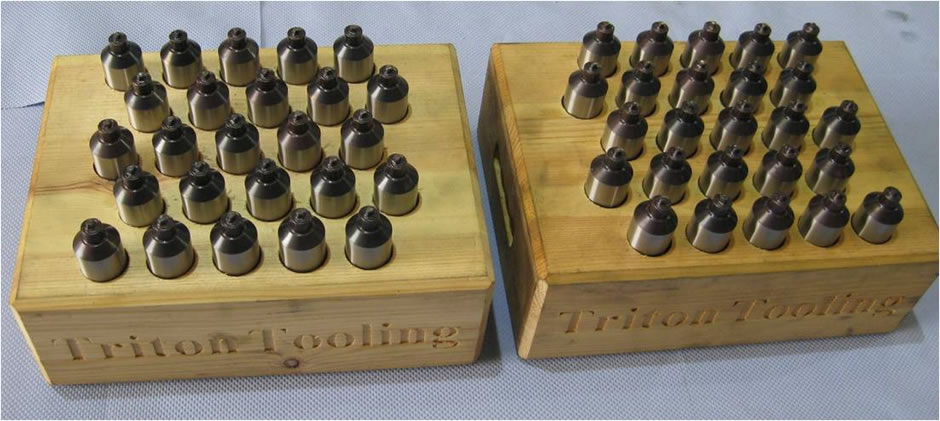

Triton Tooling has a comprehensively equipped toolroom catering for all aspects of precision engineering, design and development, and specialising in small production runs.

We are independent and reliable, working on a one to one basis with all our clients to ensure customer satisfaction.

NDT (Non Destructive Testing)

Using CNC profiling and EDM we are able to machine starter notches for fracture testing and defects for NDT (Non Destructive Testing.)

Using electrodes as small as 0.1mm thick, we are able to create artificial notches 0.25mm thick.

Material Test Specimens

Capable of handling large parts, Triton Tooling is able to prepare supplied materials, into test ready tensile, compact tension and charpy specimens, among others. Working closely with customers Triton Tooling is capable of extracting test specimens from particular parts of the material meaning that the specimens produced give the best analysis possible.